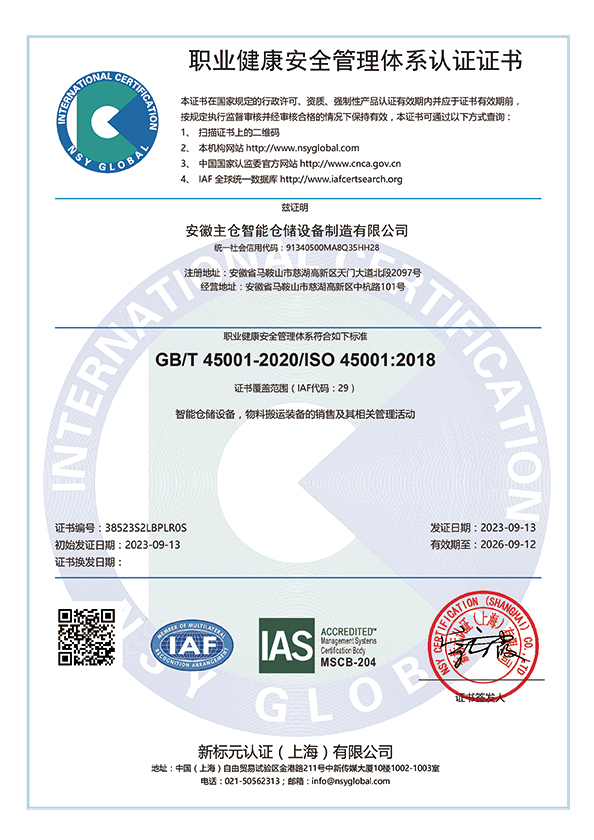

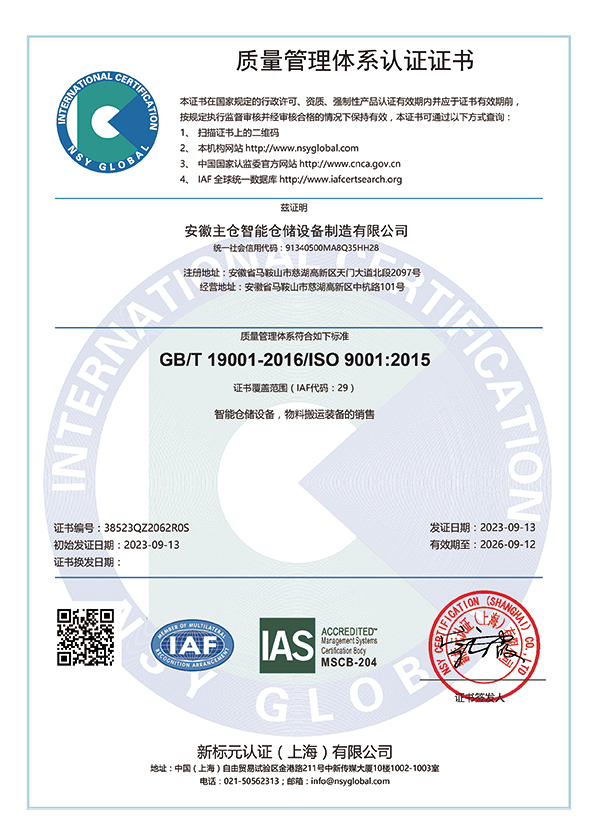

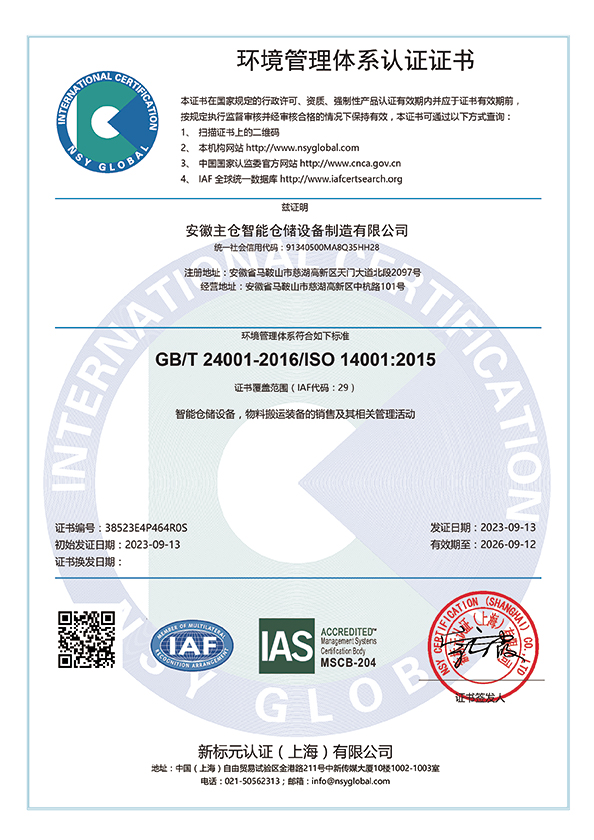

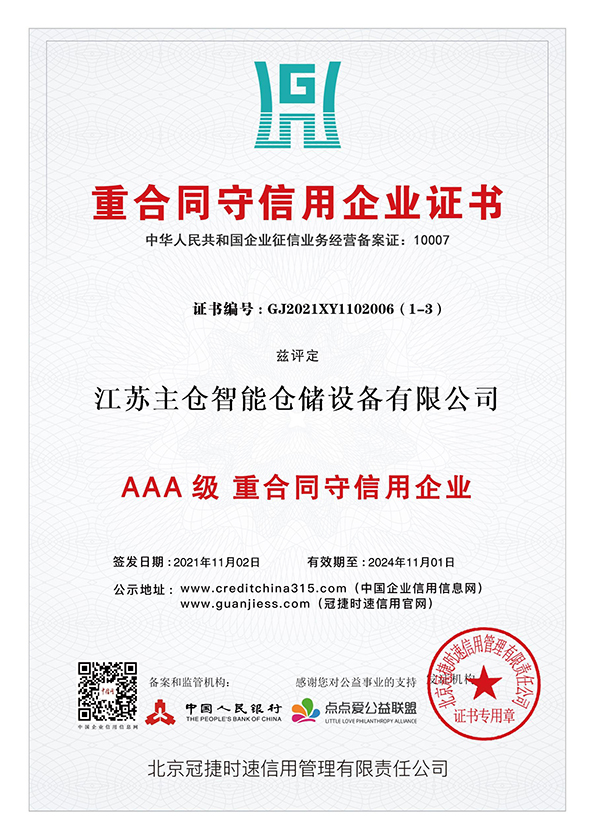

Zhucang was first established in Wuxi, Jiangsu Province in 2007 (formerly known as Wuxi Zhucang Shelf Factory). It is a certified enterprise with ISO9001 international quality management system, ISO14001 international environmental management system, and ISO45001 international occupational health and safety management system. It has long been committed to the research and development, design, production, sales, installation, and provision of integrated after-sales technical services for modern logistics system products. Zhucang always pursues advanced international management models, continuously absorbs advanced technologies from the international and domestic logistics industry and metal products industry, and combines the actual situation of its own enterprise to continuously develop new technologies and launch new products, so that the Zhucang company is at a good level in the same industry in China.

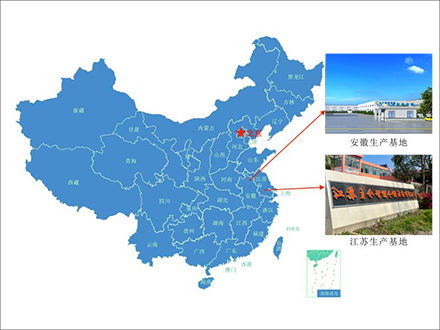

The production base with theZhucang located in Ma'anshan City, Anhui Province is planned to be officially put into operation in 2023, with a factory area of 37000m ², Total construction area 26000m ², The plan is to produce 60000 tons of warehousing and logistics shelves annually. The main processing equipment includes cold bending equipment, electrostatic coating lines, sheet metal processing equipment, etc. From feeding, rolling, welding, powder spraying to shipping, each link has a strict quality control system. Zhucang relies on advanced production equipment, modern enterprise management mode, strong technical strength, and mature production processes, strictly following national technical standards, industry technical standards, and European and American technical standards; Effectively ensuring the quality of our company's products; Zhucang always remains at the forefront of the industry. Adhere to the principle of "quality first, service first, customer first, and reputation first"; Realize the quality commitment and ensure that customers can use the Zhucang products with confidence. At the same time, Zhucang has also established 12 self owned professional installation teams and standard operations, transforming from product output to current service output, and moving towards a new stage of customization, efficiency, and intelligence in intensive warehousing; Strive to achieve 100% customer satisfaction.

In recent years, the company has completed the construction of shelves and supporting projects for nearly a thousand warehouses or logistics distribution centers for domestic and foreign enterprises, as well as the design and manufacturing of nearly a hundred non-standard metal products. Among them: LG New Energy (Nanjing) automated warehouse shelves in South Korea, Mengniu Dairy (Chabei) automated warehouse shelves, BYD and its subsidiary Fodi Battery (Shenzhen, Chongqing, Wuhan, Jinan, Yancheng, Wuwei, Xiangyang, Taizhou, Changsha, Zhengzhou) automated warehouse shelves, Araymond (Zhenjiang) unmanned warehouse automated separated shelves in France, Yuanyuan Power (Shiyan) automated warehouse shelves Large logistics warehousing projects such as the raw material warehouse shelf project of Zuming Food (Anji) and the steel platform of JD Logistics (Asia No.1) logistics line; The industry covers various industries such as new energy, food, beverages, clothing, daily chemicals, tobacco and alcohol, medicine, cold chain, e-commerce, logistics, etc., and has won high praise from many multinational and domestic enterprises, with a customer repurchase rate of over 97%.

Core products of Zhucang:

High precision shelves: automated three-dimensional warehouse shelves, four-way vehicle dense warehouse shelves, sub mother vehicle dense warehouse shelves and multi pass dense warehouse shelves, two-way shuttle dense warehouse shelves, and material box three-dimensional warehouse shelves.

Non standard products: automatic separation type fluent shelves, equipment maintenance platforms, conveyor line platforms, steel pallets, material frames, stacking racks, latent and traction AGV material racks, including various types of non-standard metal products for processing according to drawings.

Universal shelves: heavy-duty high shelves, loft style shelves, steel platforms, narrow aisle shelves, through shelves, cantilever shelves, fluent shelves, pressed in shelves and other shelf series products